Products List

Showing 1 results from page 36

Industrial grade product series

Cast Steel Floating Ball Valve

Design features:

Through hole or shrink hole structure;

Fireproof type test certification;

···

Industrial grade product series

Forged Steel Trunnion Mounted Ball Valves

Design features:

Through hole or shrink hole;

Fireproof type test certification;

Dual block···

Industrial grade product series

Cast steel globe valve

Design Features:

Rising stem external thread and bracket, lifting stem, bolted bonnet;

Thrust ···

Ultra High Purity Valves

DV7 High Pressure Spring Diaphragm Valve High-Purity and Ultra-High-Purity

Working pressure: Vacuum to 241 bar (3500 psig)

Flow Cv: 0.14~0.2

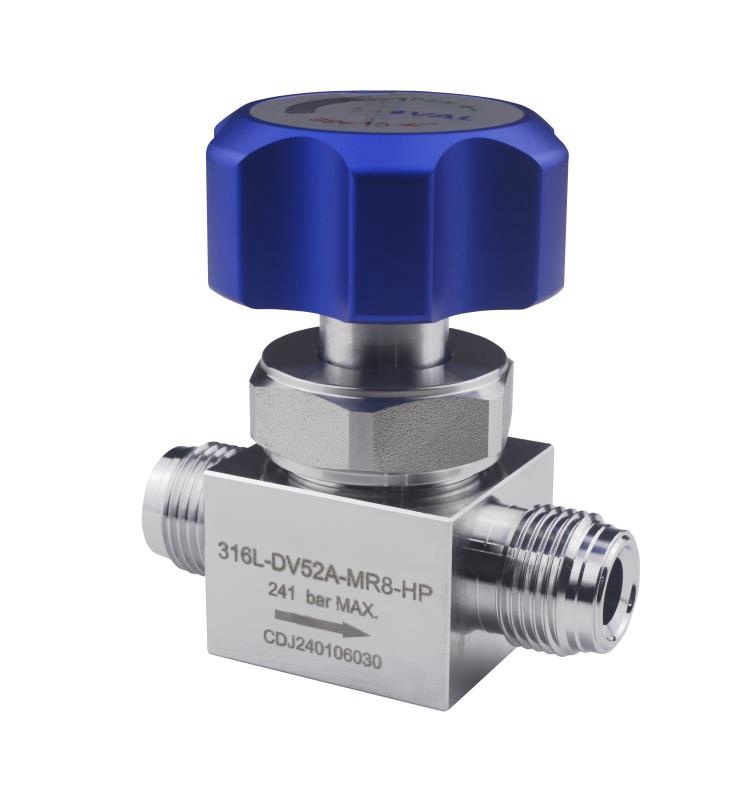

Ultra High Purity Valves

DV5 High Pressure and Small Flow Diaphragm Valve High-Purity and Ultra-High-Purity

Working pressure: Vacuum to 241 bar (3500 psig)

Flow Cv: 0.8

Water-HVAC-Gas-Fittings

Y12 Diaphragm type Pressure Reducing Valve

Nominal pressure: 1.6MPa

Working medium: water, oil, gas

Working temperature: t≤120℃

Test p···